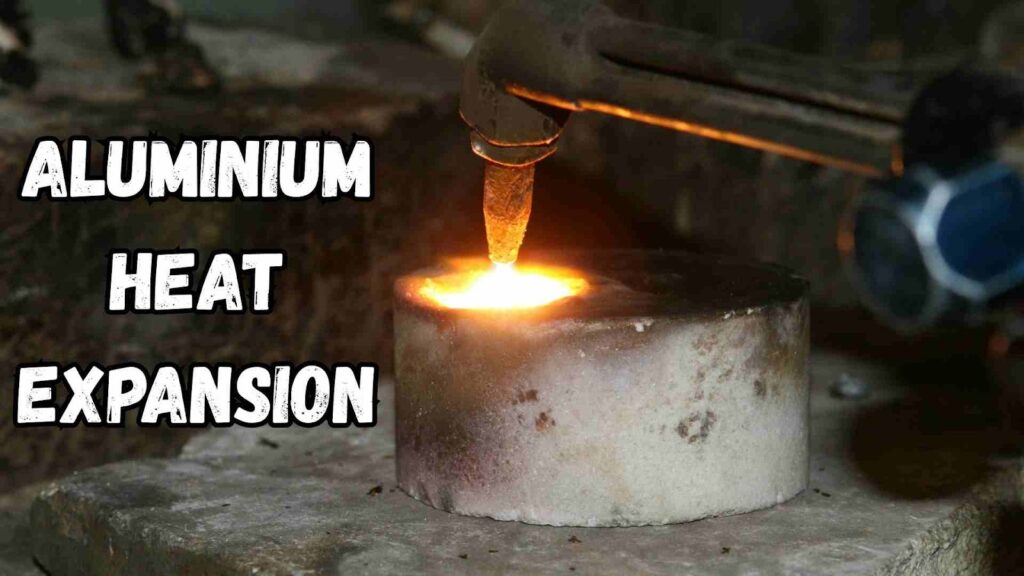

Aluminium heat expansion plays a vital role in how metal behaves when temperatures rise or fall. From everyday kitchen tools to large construction frameworks, aluminium responds noticeably to heat, making it important to understand this property.

This article explains why aluminium expands when heated, how it compares with other metals, and where this behavior matters most in real-life applications. You’ll learn about thermal expansion, coefficient of expansion, metal temperature effects, industrial applications, and engineering design considerations.

By understanding these concepts, readers can see how temperature changes influence safety, durability, and performance. Whether you’re a student, engineer, or curious reader, this guide simplifies the science behind aluminium’s response to heat in a clear, practical way.

Understanding Aluminium Heat Expansion

Aluminium heat expansion refers to the natural tendency of aluminium to increase in size when exposed to higher temperatures. Like most metals, aluminium reacts at the atomic level when heat energy causes atoms to vibrate and move apart. This physical response is predictable and measurable, which makes it especially important in engineering design, construction materials, and industrial manufacturing. Because aluminium is lightweight and widely used, understanding how it expands helps prevent structural damage and performance issues in real world applications.

Scientific Background of Thermal Expansion

How Temperature Affects Metals

When heat is applied to metal, its atoms gain energy and vibrate faster. This movement increases the distance between atoms, causing expansion. In aluminium, this effect is more noticeable than in many other metals due to its atomic structure and bonding. Thermal expansion is not a chemical change but a physical one, meaning the metal returns to its original size when cooled.

Coefficient of Expansion Explained

The coefficient of expansion measures how much a material expands per degree of temperature change. Aluminium has a relatively high coefficient compared to steel or iron. This property makes aluminium heat expansion easier to calculate but also more critical to manage in projects that face frequent temperature variations.

Importance in Engineering and Construction

Structural Safety and Durability

In bridges, buildings, and railway systems, aluminium heat expansion must be carefully planned. If expansion is ignored, materials can buckle, crack, or place stress on joints. Engineers use expansion joints and flexible connections to allow safe movement. This approach improves long term durability and reduces maintenance costs.

Industrial and Everyday Applications

Aluminium is used in window frames, power lines, vehicles, and electronics. In these cases, metal temperature effects can influence alignment, efficiency, and safety. For example, overhead power cables sag more in hot weather due to expansion, which is a normal and expected behavior.

Key Features of Aluminium Expansion Behavior

Lightweight Yet Highly Responsive

One major feature of aluminium is that it expands more per unit length than many heavier metals. This makes it ideal for applications requiring flexibility but also demands careful planning. Aluminium heat expansion is consistent, which allows accurate modeling in design software.

Predictable and Reversible Process

Another advantage is predictability. Aluminium expands and contracts uniformly when temperature changes are even. This predictable behavior supports engineering design considerations and helps avoid unexpected failures.

Advantages and Challenges

Benefits of Using Aluminium

Aluminium offers several advantages despite its expansion characteristics:

1.Lightweight material reduces overall structural load

2.High corrosion resistance increases lifespan

3.Good thermal conductivity supports heat dissipation

4.Easy to shape and manufacture

5.Recyclable and environmentally friendly

These benefits explain why aluminium remains popular across many industries.

Potential Drawbacks and Limitations

However, aluminium heat expansion can become a challenge if not managed properly. Excessive expansion may cause misalignment or stress in rigid systems. In precision equipment, even small dimensional changes can affect performance. Designers must balance aluminium’s benefits with its thermal behavior.

How Aluminium Heat Expansion Works in Practice

Step by Step Expansion Process

The expansion process follows a simple sequence:

1.Temperature increases

2.Atoms gain kinetic energy

3.Atomic spacing increases

4.Material length and volume grow

5.Structure adapts through joints or gaps

This process highlights why industrial applications rely on accurate temperature calculations.

Comparison With Other Metals

Compared to steel, aluminium expands nearly twice as much under the same temperature change. This difference is important when combining materials in one structure. Mixing metals without accounting for expansion can lead to stress buildup and eventual failure.

Use Cases and Real World Examples

Construction and Architecture

In modern buildings, aluminium panels and frames are designed with movement allowances. Architects consider aluminium heat expansion when planning facades exposed to sunlight. Expansion gaps maintain appearance and safety over time.

Transportation and Technology

Aircraft, automobiles, and electronic devices all depend on aluminium components. In these fields, metal temperature effects influence fuel efficiency, signal stability, and mechanical accuracy. Proper material selection ensures reliable performance in varying climates.

Practical Tips and Recommendations

To manage aluminium heat expansion effectively, professionals follow proven practices:

1.Use expansion joints in long structures

2. Allow tolerance gaps in precision assemblies

3. Avoid rigid connections with low expansion materials

4. Consider climate conditions during design

5. Regularly inspect components exposed to heat

By applying these recommendations, engineers and builders can fully benefit from aluminium’s strengths while minimizing risks.

Final Perspective on Aluminium Expansion

Aluminium heat expansion is a fundamental property that shapes how this metal is used across industries. Its predictable response to temperature makes it both an advantage and a responsibility in design. With proper understanding and planning, aluminium remains one of the most versatile and reliable materials in modern engineering.

Conclusion

Understanding aluminium heat expansion helps explain how this widely used metal responds to temperature changes in real world conditions. The article explored its scientific basis, practical behavior, and role in engineering design, construction materials, and industrial applications. By learning about thermal expansion, coefficient of expansion, and metal temperature effects, professionals can prevent structural stress and performance issues. Proper planning turns aluminium heat expansion into a manageable factor rather than a limitation, ensuring safety, durability, and efficiency across industries where aluminium plays a critical role.